Cable Tray Production Line

Cable Tray Production Line

Cable tray production equipment can work with different coil weights starting from 4 ton up to 20 tons. The cable tray thickness is usually between 0,5-2 mm. The line is suitable for the production of cable trays with 100-600 mm width.

Cable Tray Production Line is consisting of the following equipment:

- Coil Decoiler or Uncoiler machine

- Coil Loading Device

- Straightening Machine

- Servo Feeder

- Eccentric Press

- Punching Tools

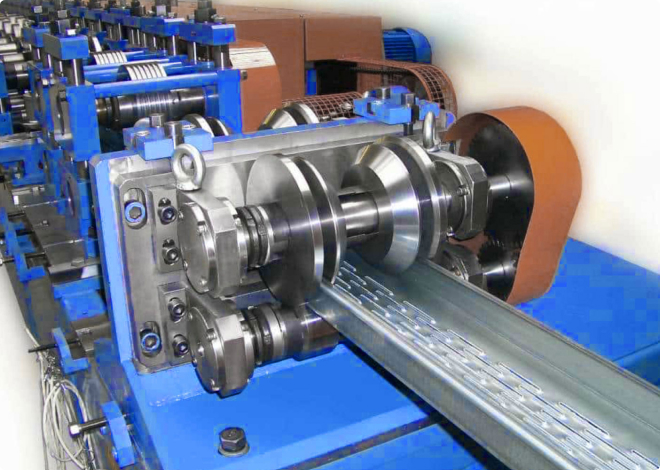

- Rollforming Line

- Stacking Unit.

Roll Forming Process

The main part of the cable tray production line is rollforming process. The line starts with the loading of the new coil onto the decoiler machine. Coil loading car or coil loading device is loading the coil onto the decoiler and Decoiler starts the uncoiling of the coil. At the next stages, straightener machine is straightening the material and servo feeder machine feeds the material to the eccentric press. The press is punching the holes on the cable trays and cut at a required length.

Further, the cut material is fed to the rollforming machien for the final forming. Rollforming machine makes the cable tray from the sheet material using different rollers. The last operation is the stacking unit, which stacks the ready cable trays properly.